Высококачественное лабораторное оборудование для сушки распылением 1,5 л

& nbsp; Лабораторные весы с распылительной сушилкой подходят для производства в университетах, исследовательских институтах и на предприятиях пищевой и фармацевтической химии. & nbsp;

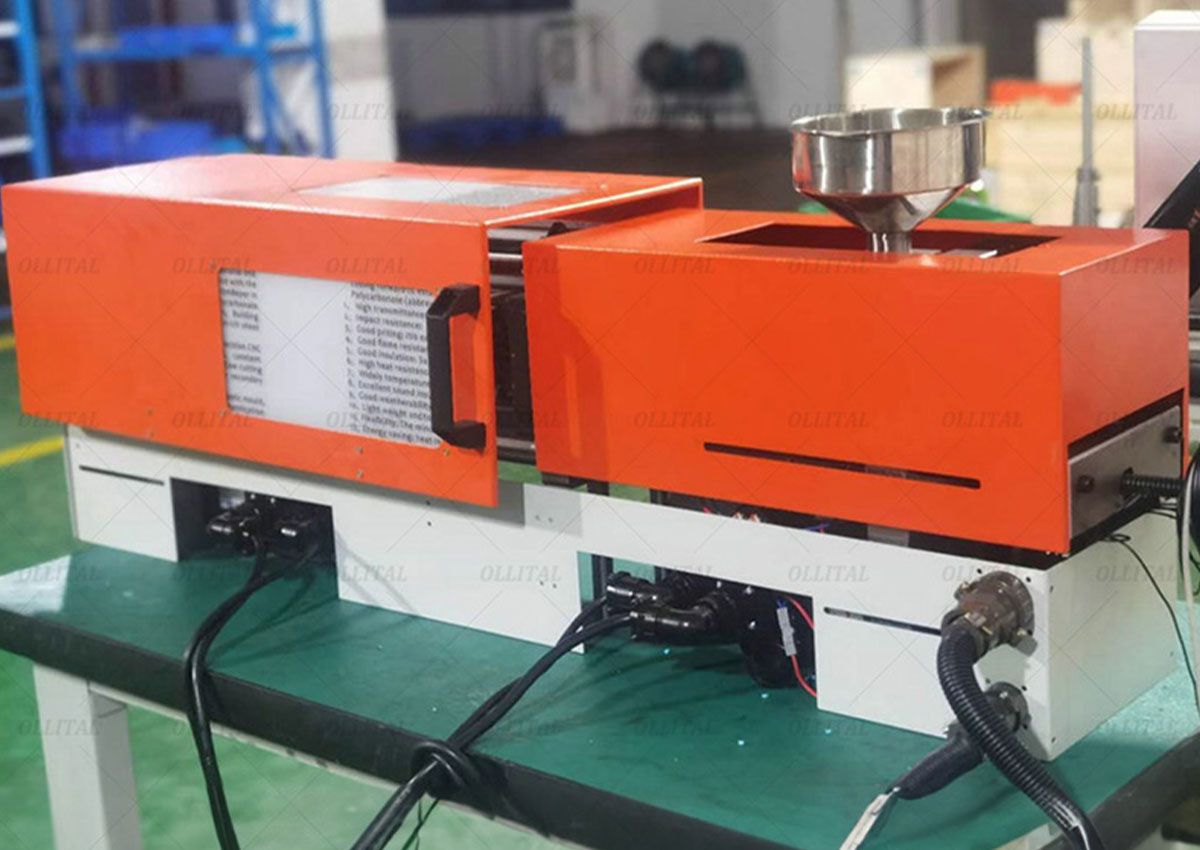

Injection molding machines are the backbone of modern plastic manufacturing, used to produce everything from medical components and packaging to automotive parts and consumer goods. Understanding the different types of injection molding machines is essential when selecting the right equipment for your production needs. Each type offers unique advantages depending on application, material, and output requirements.

Hydraulic injection molding machines are the most traditional and widely used type. They rely on hydraulic cylinders to generate the clamping force and injection pressure required to mold plastic parts.

Key advantages:

- High clamping force suitable for large molds

- Excellent durability and long service life

- Capable of processing high-viscosity and reinforced materials

Limitations:

- Higher energy consumption

- Louder operation compared to newer technologies

- Hydraulic machines are commonly used in automotive, industrial, and heavy-duty applications where strength and reliability are more important than energy savings.

All-electric injection molding machines use servo motors instead of hydraulics for all movements, including injection, clamping, and ejection.

Key advantages:

- High precision and repeatability

- Energy savings of up to 50–70%

- Clean operation with no hydraulic oil

Limitations:

- Higher initial investment

- Typically lower maximum clamping force than hydraulic machines

- These machines are ideal for medical devices, electronics, laboratory products, and precision components where cleanliness and accuracy are critical.

Electric injection molding machines are ideal for applications requiring high precision, energy efficiency, low noise, and clean operation, making them suitable for electronics, medical, and thin-wall products. Hydraulic injection molding machines, on the other hand, offer higher clamping force, strong versatility, and lower initial cost, making them better suited for large parts and general-purpose plastic products where ultra-high precision is not critical. Интернет Сервис

Интернет Сервис +86 15960821529

+86 15960821529 kevin@ollital.com

kevin@ollital.com kevinollital@gmail.com

kevinollital@gmail.com +86 15960821529

+86 15960821529 +8615960821529

+8615960821529